Recent graduate

Where is he today?

Auroral Imaging Group, Department of Physics and Astronomy, University of Calgary

Baja racing, rockets and polar bears – oh my!

I grew up in Bragg Creek, just outside of Calgary. My family spent a lot of time outdoors doing a wide variety of sports. We spent two years in Australia to experience another part of the world. I became interested in disassembling, building and rebuilding in my late teens and took to sciences in high school. This is what led me to apply for entrance to the Schulich School of Engineering. Initially, I struggled a lot in my classes, barely passing my first year, in fact I almost dropped out from sheer discouragement of my grades. I ended up dialing back to only three classes a semester for my second year to balance my job and my class work more effectively. It delayed my graduation by one year, but it was definitely worth the time. This really helped me get back on track and rediscover my passion for design and creation. I joined one of the Schulich vehicle teams and, from that year forward, I attacked my schooling with an energy I hadn’t known before. I got an internship after my third year with a space weather research group in the UCalgary physics department and went back to work for them after graduating with my BSc in electrical engineering and a minor in computer engineering. I had no idea what to expect from a job in research and, in retrospect, there was no way I could have had any idea what an opportunity it was. The most significant factors that set the job apart are the dramatic variety of tasks and skills required. Research teams are small, so everyone on the team needs to be a human Swiss army knife if they want to continue receiving funding. We design, manufacture, test, deploy and operate an array of instrumentation across the Canadian north focused on the polar-edge regions. These instruments are all fully automated with environmental control systems that support cameras (some white light, some wavelength-specific), GPS signal monitors, radio frequency receivers and a 90-foot, 4,000 element radar. In total, we have approximately 80 systems operating. This means, in a single day, I may be at a soldering station, writing python-based software systems, in the shop building containers, protective mechanisms, or in Taloyoak, hip deep in snow trying to coax a system back to life. This keeps me on my toes, makes the day-to-day interesting and keeps the boredom well at bay.

Learning how to handle frustration, struggle and failure is an enormous part of the degree as it breeds persistence, efficiency, modesty and confidence.

Lukas Vollmerhaus

BSc (Eng)’17

How did UCalgary’s Schulich School of Engineering prepare you to be an engineer?

The tongue-in-cheek answer here is, “They gave me lessons in engineering.” I expected that the content of my classes would show up very often in my day-to-day work, but the truth is that the lessons in engineering taught at Schulich are not all written on a white board. The most significant lesson I learned in school was how to manage the enormous volume of work/learning required to pass each year. The real-life applications of time management, efficient prioritization and the discovery that there are only 24 hours in a day (and sometimes you need every last one) are immeasurable. Certainly, the content of the classes is also valuable, but they are all building blocks for higher learning and understanding. So no, I don’t use the content of say Digital Circuits in my day-to-day, but the design concepts and processes taught in the course are things I use in my day-to-day. Learning how to handle frustration, struggle and failure is an enormous part of the degree as it breeds persistence, efficiency, modesty and confidence. These are the cornerstones of engineering.

Who were your UCalgary mentors?

I think many of my mentors were relatively unaware of their mentorship, but there were a few professors that I looked up to, usually due to their cool mannerism, modesty and intelligence: Dr. Mike Potter, Norm Bartley, Dr. Chris Macnab, Dr. Craig Johansen – to name a few. I can’t understate the importance of the Baja team here as well, having fellow students in higher years that I could easily ask questions and get a sense of normality from was invaluable. Finding out that I was far from the only one struggling, and that there was light at the end of the tunnel, was crucial to the success of my degree.

What were your Schulich School of Engineering highlights?

I had two major highlights in my schooling career. The first, stretched over my last four years, I joined Schulich Off-Road, the SSE Baja SAE racing team. Each year the team designs, manufactures and races and off-road buggy. This is when I really started to pick up skills outside of my electrical degree. While the car has very little in terms of an electrical system (brake light and engine kill-switch) I was surprised with the amount of electrical work that goes into a primarily mechanical system. The testing, verification and monitoring of the vehicle’s health require extensive electrical and computer work. You can’t present the judges with a frame that SolidWorks said wouldn’t fail without having the test data where you attached strain gauges and built a data logging system to prove your frame was as strong as you thought it should be. Even so, there was so much work in fabricating the vehicle that I gravitated to that most of all. The amount of metal work in turning 15-foot sections of DOM tubing and plate steel into a rolling chassis with suspension is incredible. Grinding, welding, plasma tables, wire wheels and torches were all foreign to me when I started with the team and, by my fourth year, I was sole welder for the chassis and suspension. There are so many lessons taught going through a design cycle with a fixed-end date and performance requirements. Ultimately, the hardest lesson is how to work well as a team through the entire process. Short design projects, in class, really don’t teach the kind of co-operation required in a real, full-scale design project. If one system team doesn’t talk to another during design, you end up with a car that requires the engine to be removed in order to take off a suspension arm, far from ideal in the pit (this isn’t theoretical, it actually happened). If you drag your feet, or are anything but committed, your team can’t carry you. You are either replaced, or the vehicle fails in competition (or never makes it to competition). I have never worked harder at anything else in my life than with the Baja team. I have never enjoyed working on something as much as I did on that car.

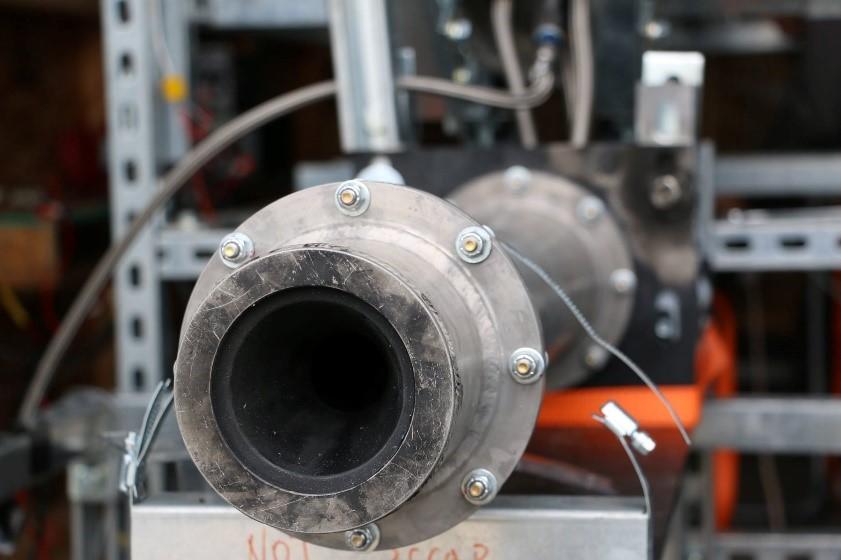

My second highlight was my capstone project. I was invited to join a team interested in designing a hybrid-fuel rocket engine. This does not mean an electric engine, but refers to the physical states of the fuel; the common choices are solid paraffin wax fuel and liquid nitrous oxide as an oxidizer. Who can’t get excited about rockets right? I had no idea how much work it was going to be, the amount of research just to figure out what kind of paraffin to use, or what micro-controllers even have a chance of reacting to a fuel imbalance or extinguish event in time. There were so many little challenges along the way, we could have easily created 10 other capstone projects out of the questions we wanted to answer for our design decisions. A perfect example was the task of setting the paraffin; it needed to be a certain width around the inner wall of a Kevlar tube. Do you fill the tube and then bore a four-inch-wide, 24-inch-deep through-hole? Do you set a second tube in the middle and remove it once the wax hardens? The ideal way is to pour the wax into a tube and spin it while it cools: all other methods leave a reasonable chance that the center bore is off-axis or inconsistent. So now, to make a thing that spins an eight-inch tube at 1,800 RPM. We ended up deciding that wasn’t worth spending time on, and went with the tube form placed in the wax - to be removed once the wax was cool. But we just about spent a valuable couple of weeks just building a thing that would spin a tube to ensure even wax distribution. Testing something like this was a giant challenge; we had predicted enormous amounts of thrust, 15 feet of flame and sound equivalent to a jet engine. Who’s going to let a handful of engineering students do that? We were fortunate enough that (after much searching through the universities’ properties and loading bays) the Rothney Astrophysical Observatory had a pad we could drop a sea can on and fence off (ensuring no crispy, unaware wanderers). Unfortunately, I was at a Baja SAE competition when the engine was first fired, but when I got back, it became very clear that this was the coolest thing I had ever had a hand in building. Of course, there were problems. As if a group of engineering students could design and build a liquid/solid fuel rocket from scratch and have it perform exactly as intended. The burn was intended to last for 13 seconds but the first burn lasted two seconds because it melted the wax faster than it combusted and most of it flew from the nozzle in globs. We blew pressure sensors through the wall of the combustion chamber (very thankful we lined the walls of the sea can with eight inches of sand), we had non-ignition events and controller failures. The rocket didn’t fly at competition that summer, but a year later – once the team had the chance to polish out the issues – it took off from the Canadian Forces Base Suffield.

Both the rocket engine and the Baja team have shaped who I am as an engineer and as a person. The more skills you can pick up in your degree (and extra-curricular activities) just pushes your resume closer to the top of any employer’s stack.

Finally, the job I have in space weather research offers some unique opportunities and, with those, come some unique hazards. Many of our sites exist solidly in the center of polar-bear territory. Polar bears (for those not familiar) are the only predatory bear, they are also the largest in both size and weight. Humans truly are in their food chain and they are quite intelligent, known to memorize people’s daily routines, stalk and wait for the right time of week to catch a snack. Our farthest north site, Resolute Bay, regularly has bears in town. My closest encounter happened there; luckily, it wasn’t a surprise and ended well. The unfortunate part of the story is that the reason for the bears’ presence was a pile of burning garbage. The town is on the north side of the Northwest Passage; this means it is too expensive to ship garbage back to a processing facility, so the town has to burn it. The saving grace is the town’s attitude towards the bears. I was finishing up my trip there and one of the last steps was to take care of the garbage created during the work. We talked with ATCO (who effectively run the town) about how to take out the garbage. Turns out there was a procedure; it requires four people and two trucks. You get your garbage in one truck (in the cab), the first truck drives onto the dump, honking and revving the engine to make as much noise as possible to encourage the bears to waddle a few feet away from the pile, while the second truck has one person drive and the other crouch in the back seat with the bags. The first truck is constantly monitoring and following the bears to keep them at a distance while the backseat person in the second truck sticks the bags out the window and onto the pile. Both trucks then retreat, and the bears re-claim their castle. This was one of the scariest but coolest moments in my graduated career; it’s not often you get to see a polar bear and cubs. What struck me as unusual, and quite thoughtful, was that the town and ATCO had simply worked out how to safely co-exist with the bears. In many southern communities a bear in the dump is often destroyed.

What is your advice for new engineering students?

Do not fear! It is difficult, you have no idea what you are in for, and you are going to have to work harder than you ever have. You thought you were smart in high school? Welcome to a much bigger pond, little minnow. BUT, if you push, give it everything you have, and more, you can come out the other end with a wicked experience. Take it seriously; you are spending $500 per course. Make that money worthwhile. For so many people, university is the only purchase you make that you try to get the least value out of. Study hard and study with others (this is critical) so you can both teach and get taught if you are excelling or struggling. Join a team! There are so many available: Baja SAE, Formula SAE, Zeus electric bike, Solar car, SOAR. At least half of what I took away from my degree came from experience on a team. Lastly, blow off steam. You can’t expect to spend four years doing nothing but crushing textbooks and come out the other side sane. Go to a few parties, and spend time playing sports, going outside and getting some mountain air. Life is still happening around you: enjoy it. You must maintain your mental health as well as your grades. The two go hand in hand.

My final piece of advice has been the most valuable for me, and goes beyond advice for engineering students to all engineers. Be modest; admit when you make a mistake. No good has ever come from pretending a problem doesn’t exist or passing the blame. The most efficient way to correct a mistake is to admit it, and figure out how to ensure it is not made again. The best engineers leave their egos at the door, collaborate, make mistakes and fix them.

You can’t be an engineer, and design and create, without messing up; it just happens. The only control you have is how you handle mistakes when (not if) they happen.

What is your life beyond engineering?

I still am an avid outdoors person. I got really into climbing after graduation. I back-country ski in the winter. After being so involved with the Baja team, I found a large hole in my life and I decided to fill it with more car stuff. I learned how to repair my own vehicles and have built a couple of vehicles I have raced in (much more relaxed) competition. Working on friends’ vehicles provides a steady stream of beer money as well. Maintaining a work-life balance took me a while after graduating, a good year and a half before I felt I was enjoying life as much as I should. A job is a job; it gets you money to do the things you want to do in your free time. It took me that long to realize that I had to make sure I was doing the things I wanted and not just working.

What does it mean to you to be an engineer?

Well, that’s kind of a tricky question - something the ethics course is really all about. But, for me personally, being an engineer goes hand-in-hand with being a good person. You can’t have one without the other. You have a responsibility to imagine, design and create for the rest of the world. You must protect those using your designs, you must protect the environment, and you have to think about any impacts your designs might have. You must be a role model for anyone else who is an engineer or wants to become one. You must show the world how useful science can be. And, you must provide a vision for the world to work towards. We, as engineers, are responsible for the future and what state we are in when we get there.